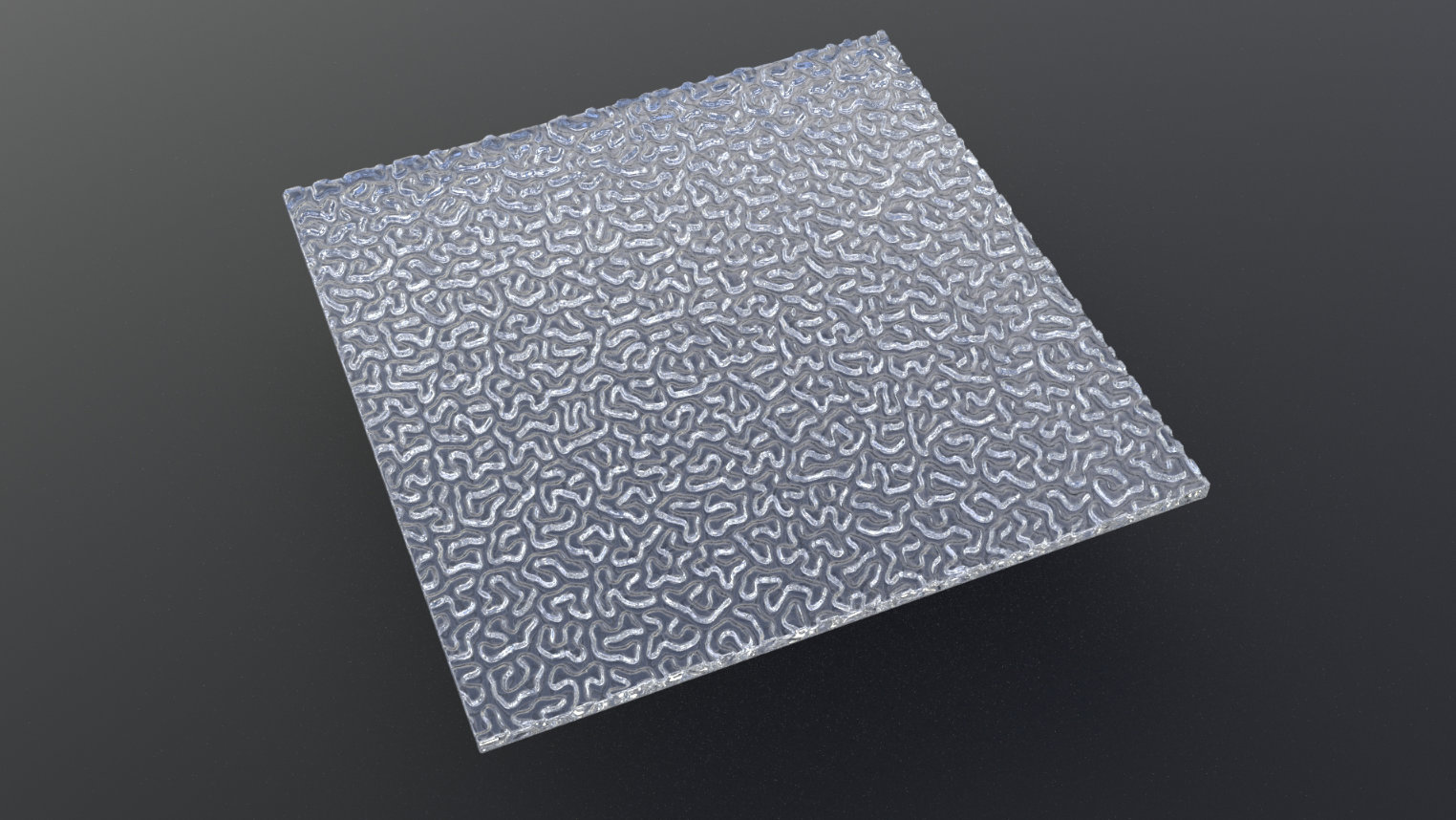

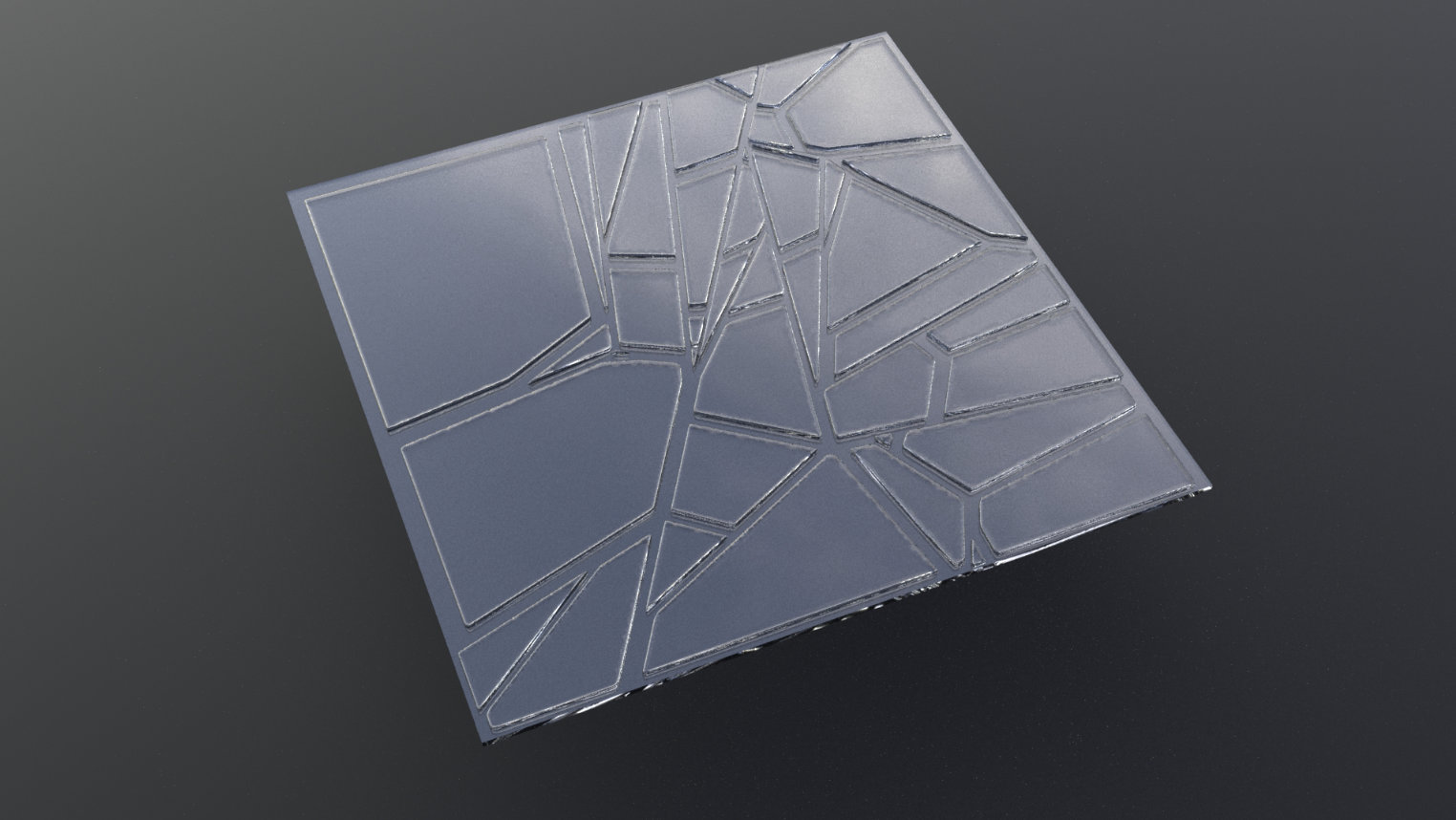

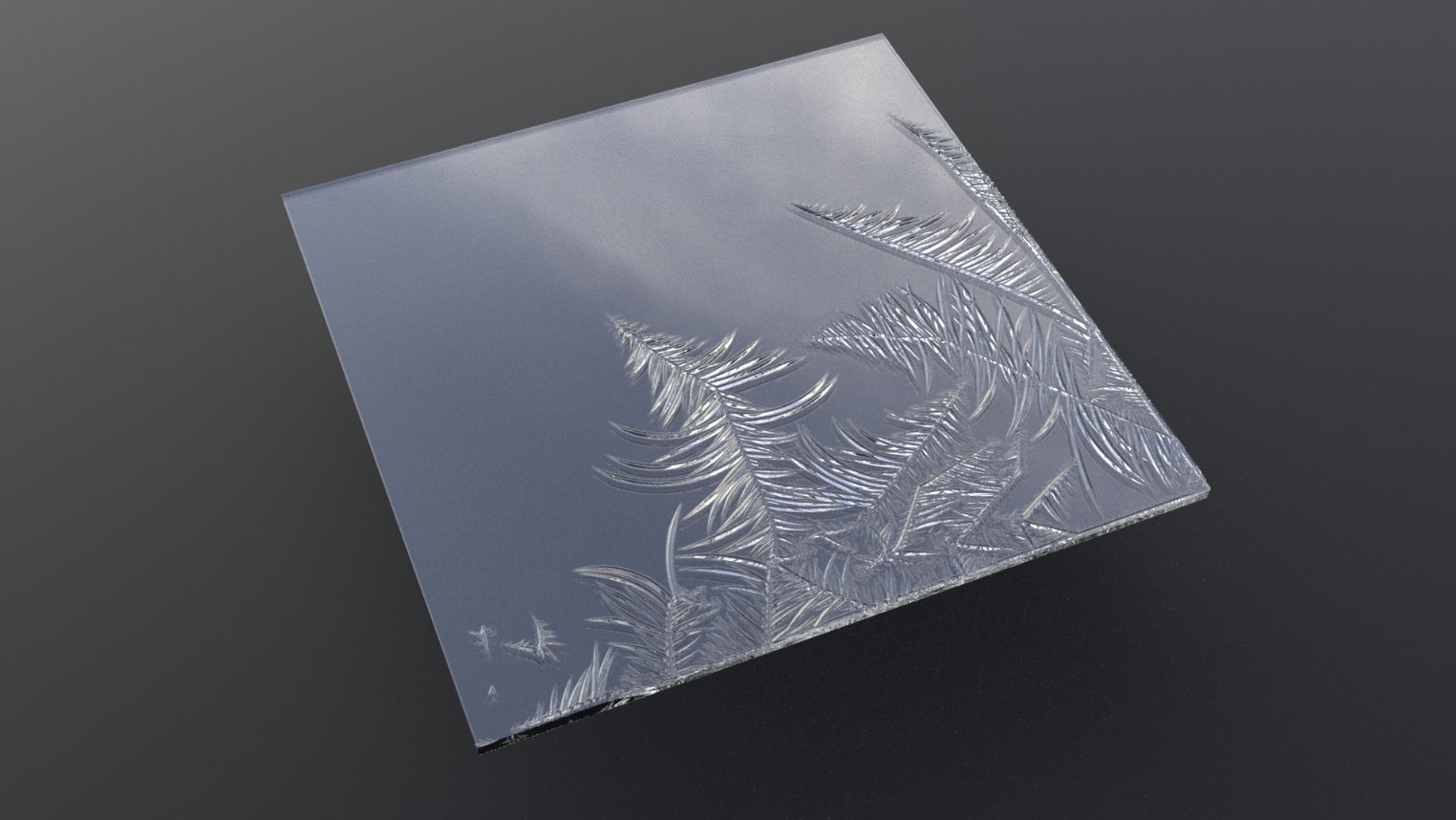

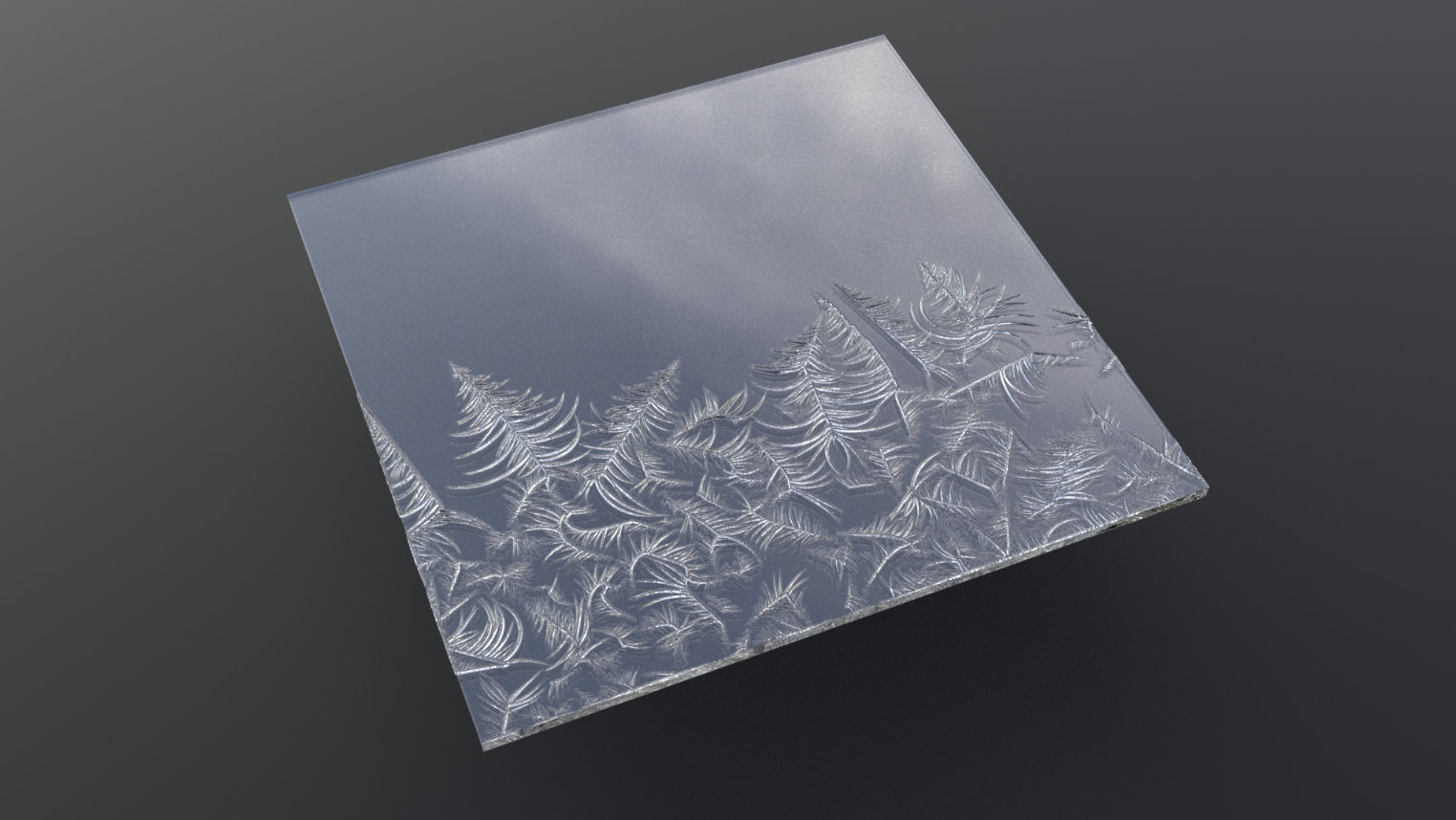

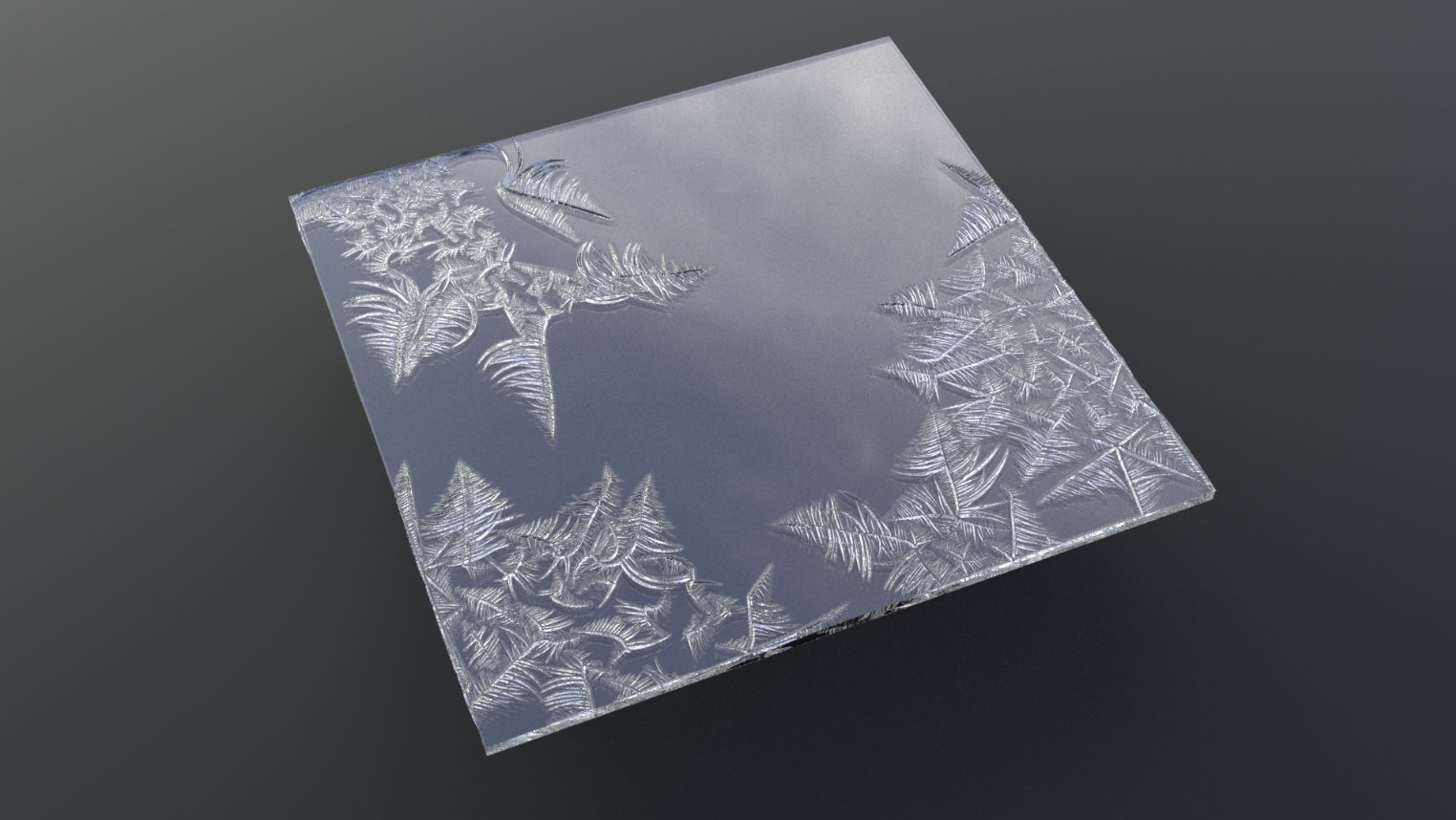

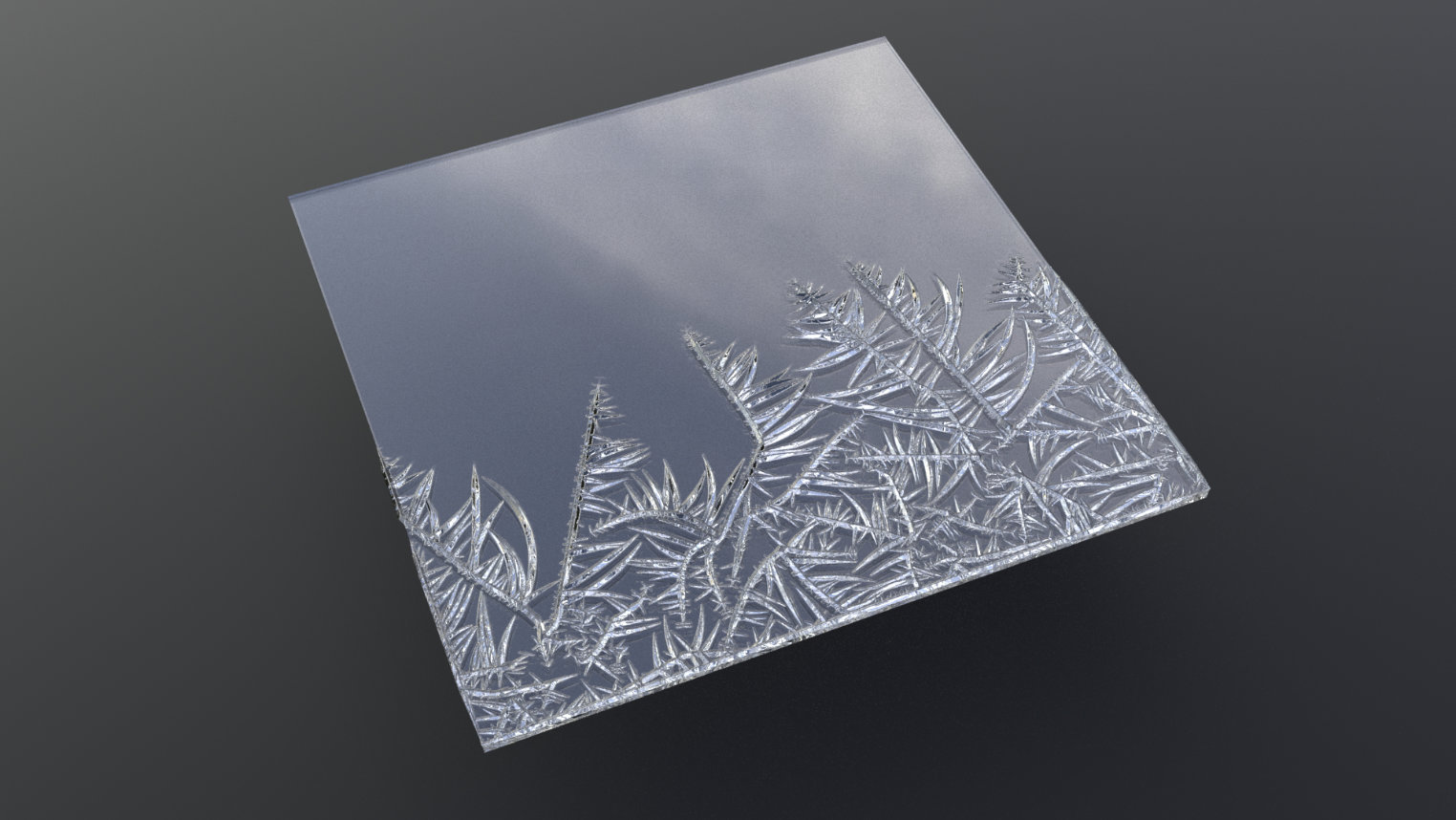

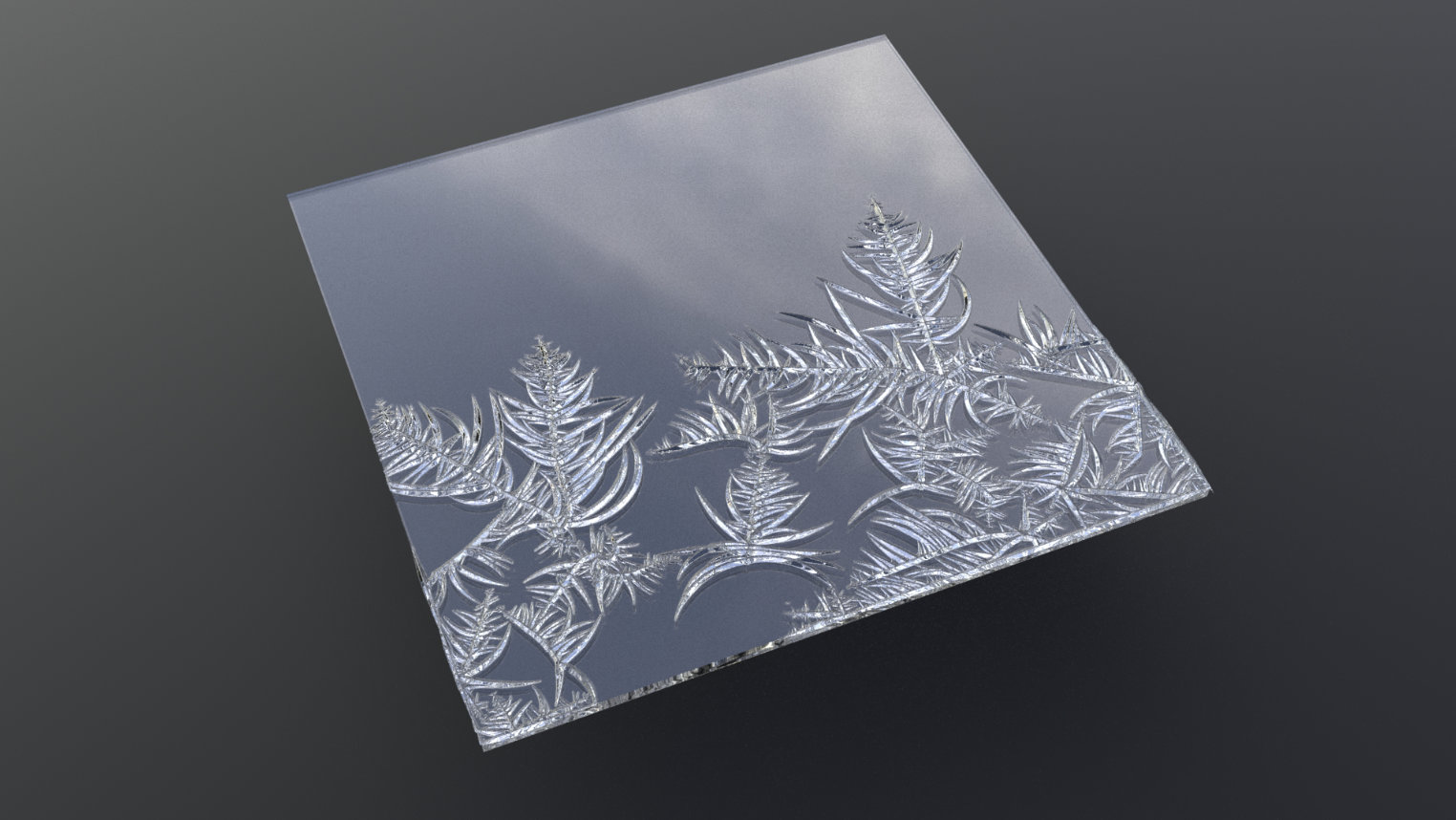

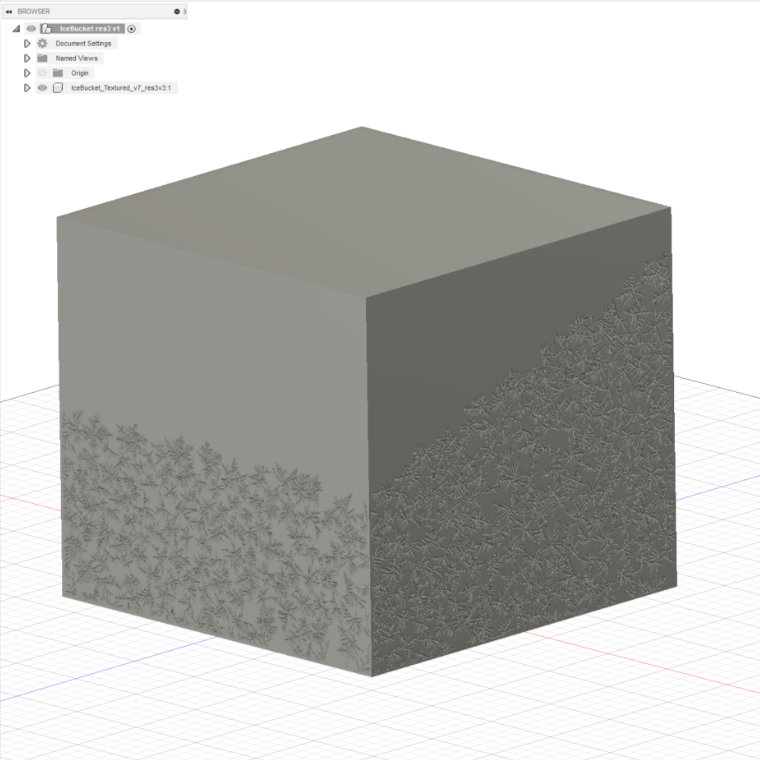

Frost Texture

Generative design for mass manufacture

This project features the development of a realistic frost texture which can be used for injection moulding by a beverage company. The key challenge was to ensure interoperability between the generative design pipeline and traditional CAD software. Establishing a workflow to interchange between these radically different workflows enables the use of generative methods without requiring a manufacturer to radically adapt their process.

The generative algorithm allows for the creation of variations and the option to grow around technical features, logos and other parts that need clearance. Usign clear resin and SLA print was made to test the physical look and feel of the texture. The outside facing surface is completely smooth and the crystals are embossed on the backside giving a 3D effect to the texture.