Sonoform

Programming materials with sound

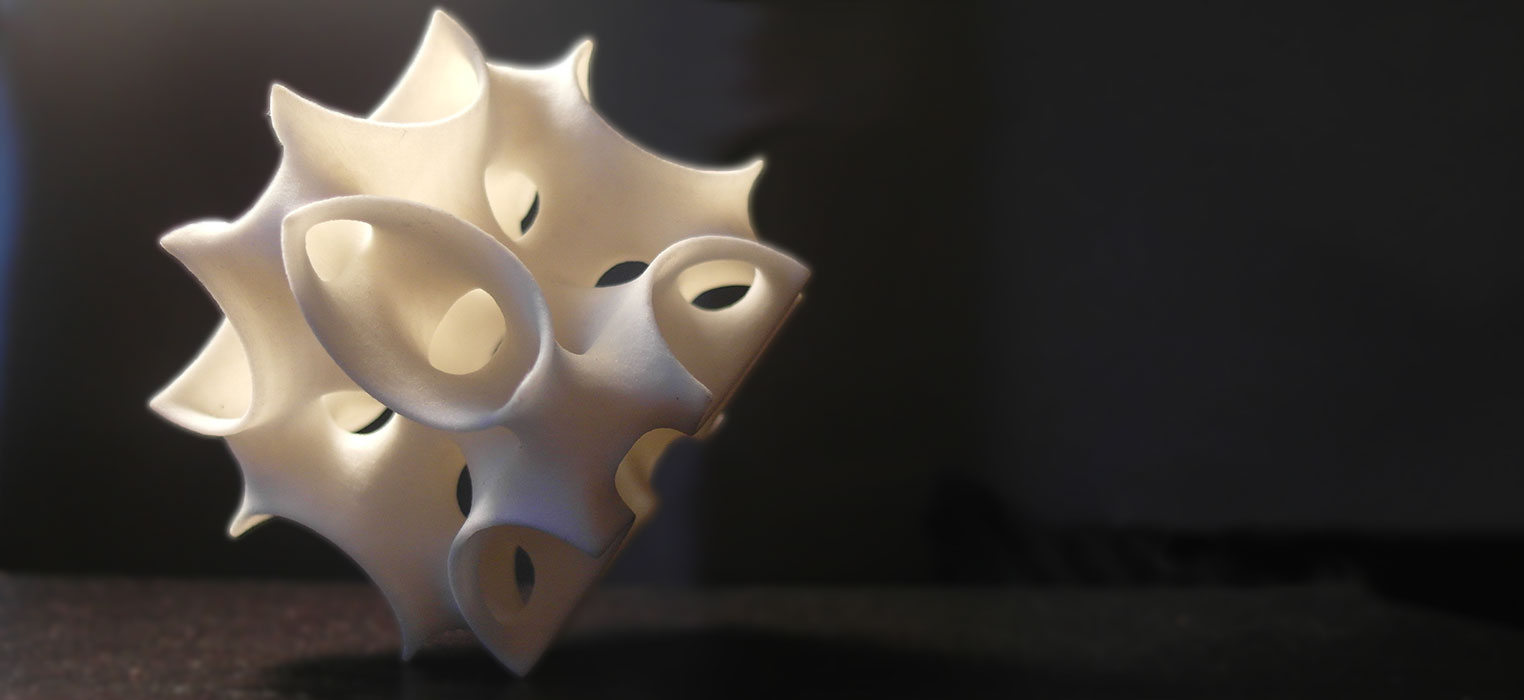

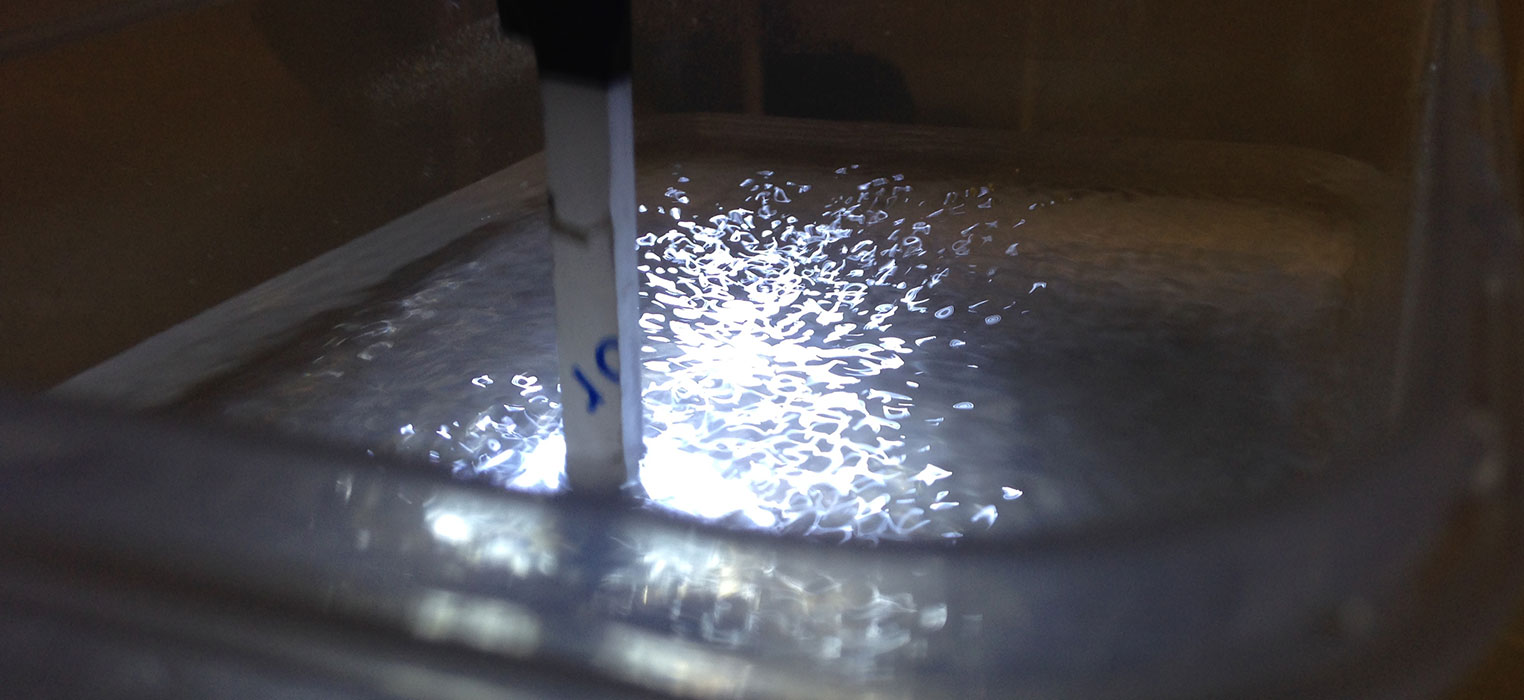

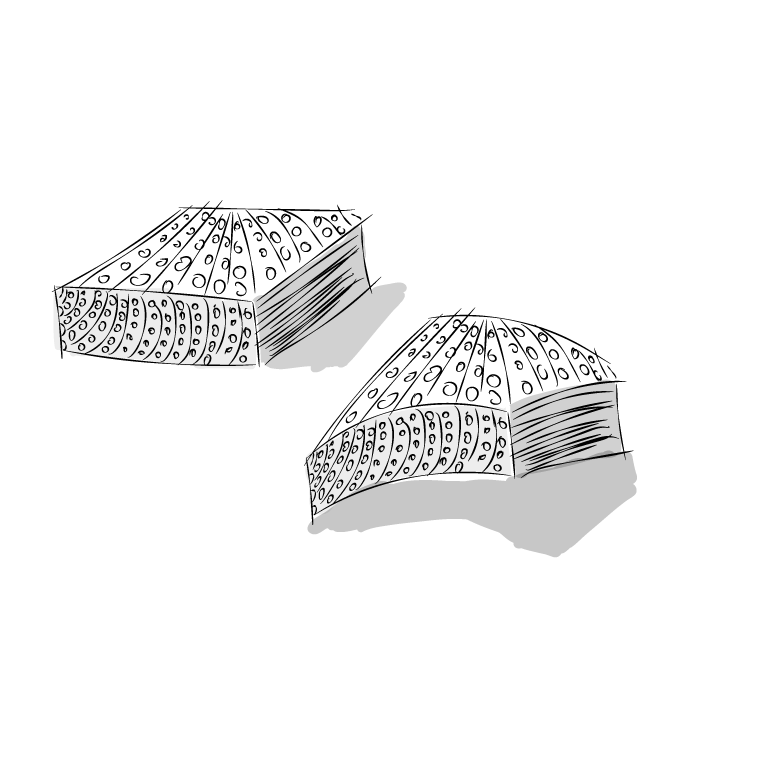

Sonoform is a new production technology that can be used to rapidly program material properties on a large scale. The technology uses sound to position particles in a liquid. By resonating the liquid, particles are positioned in intricate structures. Once positioned the particles can be fused into solid structures through electric current or microwave sintering.

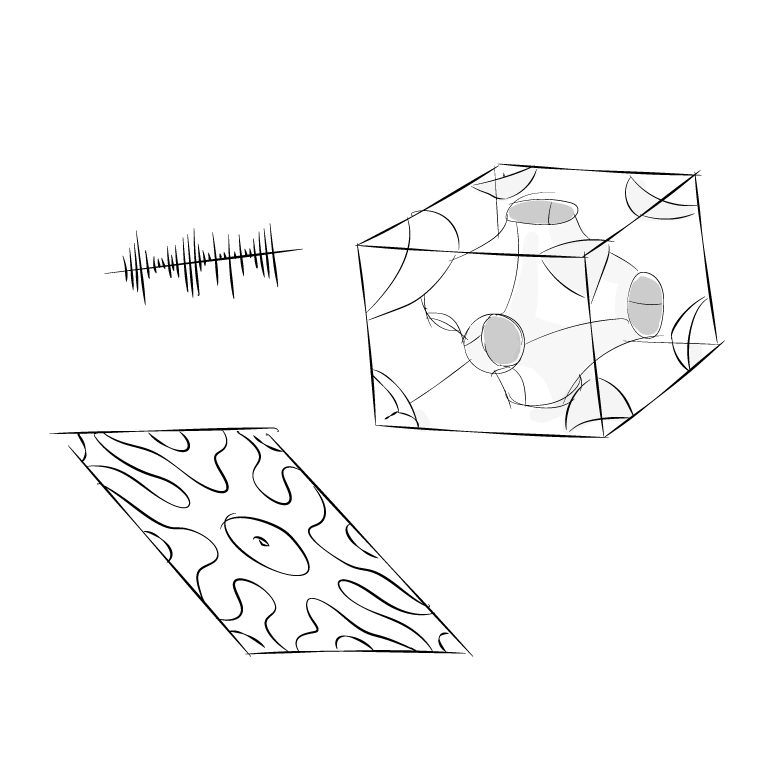

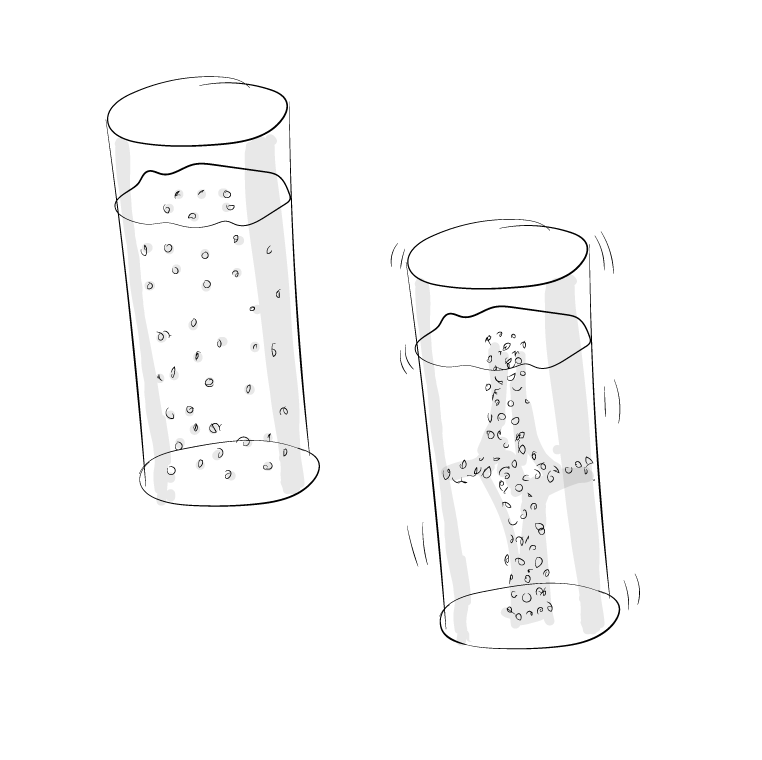

Sonoform can be applied to any shape of mould and can even be used with solid objects inside the mould. The created structures will be inherent to the shape of the mould and the objects it contains. By using higher resonant frequencies, known as harmonics, different structure densities and properties can be achieved.

“Can we program a material by listening to its inherent properties?”

Opposed to other additive manufacturing technologies Sonoforming takes a holistic approach to generating structures. The whole structure is positioned and fused in one go. There is no excess material and the suspension liquid is reusable. The scale of the created structures is only limited by the vibrating power of the resonators used. Because Sonoform leverages the natural resonant frequencies of the structure the required energy is relatively low.

The structures generated are 3d Chladni patterns. Effectively it generates complex minimal surface structures between the nodes of the standing soundwave. Sonoform is currently still in its research phase, but its future potential is very promising.